Freeman Technology

Research and developement

For 20 years, Freeman has continuously invested in research and development, hiring professionals in wheel design, new material development, forging and forming technology, heat treatment, precision machining, surface finishing, and composite materials. Beyond supporting product development, testing, and validation, we maintain close ties with scientific research and educational institutions to enhance our technical capabilities. By staying in close contact with customers and receiving market feedback, we continuously improve the performance of our forged wheel product.

Design

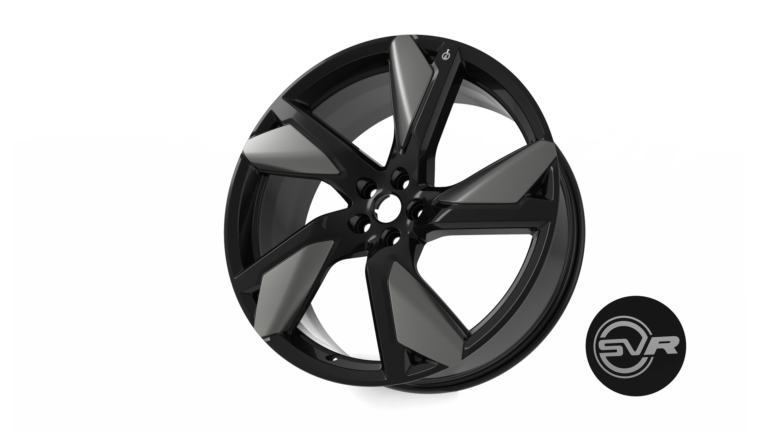

Our technical design team possesses the expertise in design, engineering, and manufacturing required to produce the forged wheels our customers need, utilizing Computer-Aided Design (CAD), Computer-Aided Engineering (CAE), and Computer-Aided Manufacturing (CAM). We establish parameters for style design, structural analysis, aerodynamics, dynamic motion, spatial use, static and dynamic strength, and fatigue resistance to provide lightweight design references that meet customer demands.

During the design and development phase, finite element analysis is used to calculate the optimal structure, shortening lead times, reducing costs, and delivering optimal lightweight designs. With capabilities in 3D design, structural design, high-quality curvature modeling, motion simulation, finite element analysis, and reverse engineering, we provide bespoke products for customers seeking a streamlined style.

Freeman wheels

Check how we work

Appearance

Special Color and finishing meet your customize requirements.

Fully Painted

Fully Painted offers a classic surface finish, with the capability to develop different paints for special colors. Combined with background painting using professional powder varnishes, oil-based paints, or water-based paints on our automated production line, we present a velvety product surface.

Bicolored – Natural Aluminum Color + Selected Color

After polishing various positions and angles with professional techniques, we apply special masking to the polished areas before painting with different colors. This process creates a bicolored appearance that combines the glossy luster of aluminum with the chosen color.

Bicolored – Two Selected Colors

Using multilayer painting and baking techniques, along with special masking, we create a high-quality bicolored visual effect. This accentuates a strong sports style in our products.

Ceramic Polish

Professional polishing equipment optimizes the surface finish, maintaining an even luster and sharp, glossy effects without compromising brightness. Combined with professional painting techniques, we deliver a mysterious matte effect in the appearance.

Mirror Polish

Our professional polishing equipment enhances the natural color and luster of aluminum, delivering a mirror-like effect.

PVD Vacuum Plating (Sputtering)

PVD vacuum plating, or sputtering, is a power-coat for wheels that provides the appearance and feel of chrome without adding extra weight. It’s a special painting technique using metal paints to present a mirror-like appearance.

Multilayer Painting with Lathing and Milling

Combining multilayer painting with lathing and milling techniques, we create a clean, geometric gradation effect. Often used on extremely high-end custom products, manual fine grinding and polishing are implemented post-machining to present a unique visual effect.

Accessories

Anticipating future demand for lightweight products, we help customers develop carbon fiber or plastic accessories, offering fastening solutions and insertion/withdrawal testing services. Beyond creating rich visual effects with our patented multilayer painting technique with lathing and milling, we also meet the demands for lightweight, multicolor, and composite materials use.

Custom Patterns

We offer custom patterns at designated positions using techniques such as laser engraving, pad printing, and HRNT. Protection is also provided to prevent patterns from damage by exterior wear.